What is Tempering in the Food Manufacturing Industry?

Tempering, also known as defrosting or thawing, remains an ever-crucial part of the food processing and manufacturing industry, allowing bulk ingredient product to be stored at frozen temperatures and dispatched as and when required at the deep chill, chill or ambient temperatures required by specialist manufacturing equipment. The tempering process, which once involved substantial drip loss and potential quality damage to stock, has changed over the years.

Modern equipment and processes, like that used by Magnavale in our Microwave tempering suite, significantly reduces these drawbacks and guarantees consistency in both output temperature and high product quality.

What is Microwave Up-Tempering?

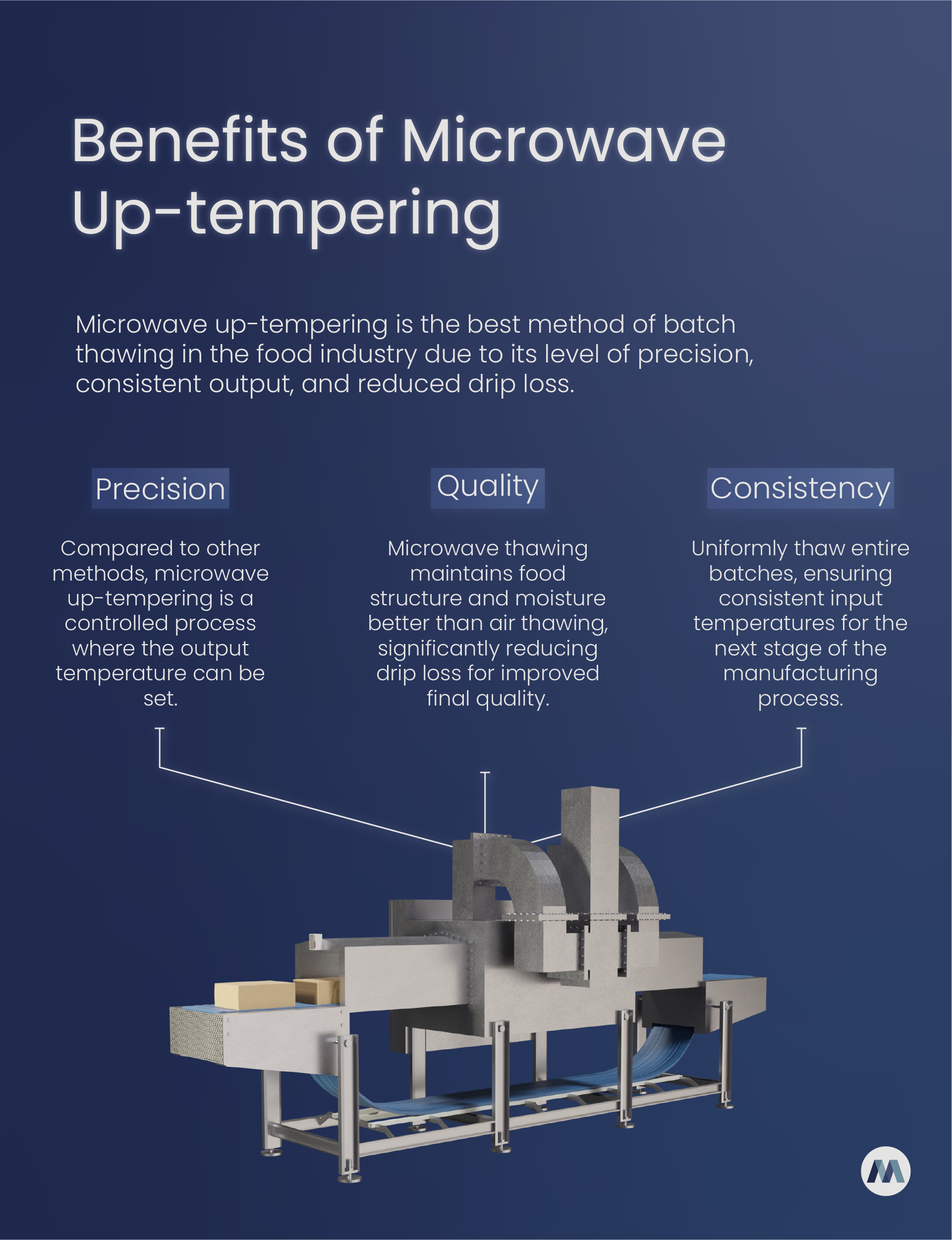

Microwave up-tempering is a technique that uses specialist industrial microwaves to heat frozen food to a desired temperature quickly and consistently. This technique helps to reduce the thawing time significantly, thus minimising the risk of bacterial growth, drip loss and loss of quality.

The principle behind the process is that microwave energy is absorbed by the water molecules present in the food, which causes the water molecules to vibrate and generate heat. This heat energy is then transferred to the surrounding food material, which causes the temperature to rise and the frozen food to thaw.

What are the Benefits of Microwave Up-Tempering?

There are many advantages of using microwave up-tempering over other methods. The process is much faster than traditional thawing methods, such as air thawing or water thawing, and can be completed in a matter of minutes instead of hours. On top of that, the end product achieved with microwave up-tempering is much more consistent, with an even temperature achieved throughout the food product. Lastly, as the thawing process is much quicker and can save energy, making it a more sustainable practice.

The Importance of a Perfectly Up-Tempered Products

Under-tempering and over-tempering can cause substantial problems in food production. For example, under-tempering ingredients like meat and dough can lead them to be too hard or stiff going into machinery used for mincing, slicing, or kneading. This puts excessive strain and stress on the mechanical parts, leading to increased wear, jamming issues, and potential breakage. While over-tempered products resist proper shaping and processing, which reduces yields and productivity.

Ensuring proper tempering is essential for protecting processing equipment, maximising efficiency, and delivering the best final product. Whether proteins, dough, or other foods, maintaining precise control over temperature transforms the ingredients into workable states suitable for further food processing.

Tempering at Magnavale

Our cold store in Chesterfield is home to Europe’s largest up-tempering suite. We use an effective and efficient two-step approach to up-tempering. The first step involves using microwave up-tempering technology to take products from deep frozen temperatures to either a deep-chill or chilled state.

Using the combination of microwaving and rapid air, we can take products from frozen to chilled temperatures quicker than other alternatives. While the microwave up-tempering process can take food products from -18°C to -3°C rapidly, the second step of our tempering process, known as rapid-air up-tempering, is used as a finishing touch, slowly and carefully bringing temperatures of the food products to the desired temperature specified by the customer.

We also offer various services that can be used in conjunction with our up-tempering services, such as frozen/chilled storage, labelling, date coding, packing and more.

What Food Products Can Be Tempered?

Some examples of foods that can be tempered include:

- Frozen meats such as beef, pork, chicken, and fish,

- Frozen baked goods such as bread, pastries, and pizza dough,

- Frozen fruit & vegetables,

- Frozen ready meals,

- Frozen soups and sauces,

- Other frozen ingredients such as confectionary fillings.

It is important to note that the specific process for up-tempering will vary depending on the type of food products being up-tempered. We conduct validation trials for all our customers to ensure food ingredients are thawed effectively. In these validation trials, we can determine how long your product will take to defrost. For denser products, like fats or proteins, the process will take significantly longer compared to lower-density products, such as most bakery goods.

Contact Us

If you are interested in our up-tempering services, or temperature-controlled solutions, please enquire below.

More on Up-Tempering

Rapid Air Up-Tempering

In the food industry, maintaining product quality while efficiently managing temperature transitions is crucial. Rapid Air Up-Tempering is...

How Microwave Tempering Works

How Microwave Tempering Works for Food Products Intro; Microwave tempering, or defrosting is an advanced industrial technique that allows...

Food Warehousing Services: Creating Efficiencies in your Cold Chain

As well as providing warehousing for the food sector, at Magnavale we provide a vast portfolio of value-added services which can be...

Contact Us

Head Office:

Magnavale Ltd, Park Road,

Holmewood Industrial Park,

Chesterfield, S42 5UY