Blast Freezing for Bakery Products

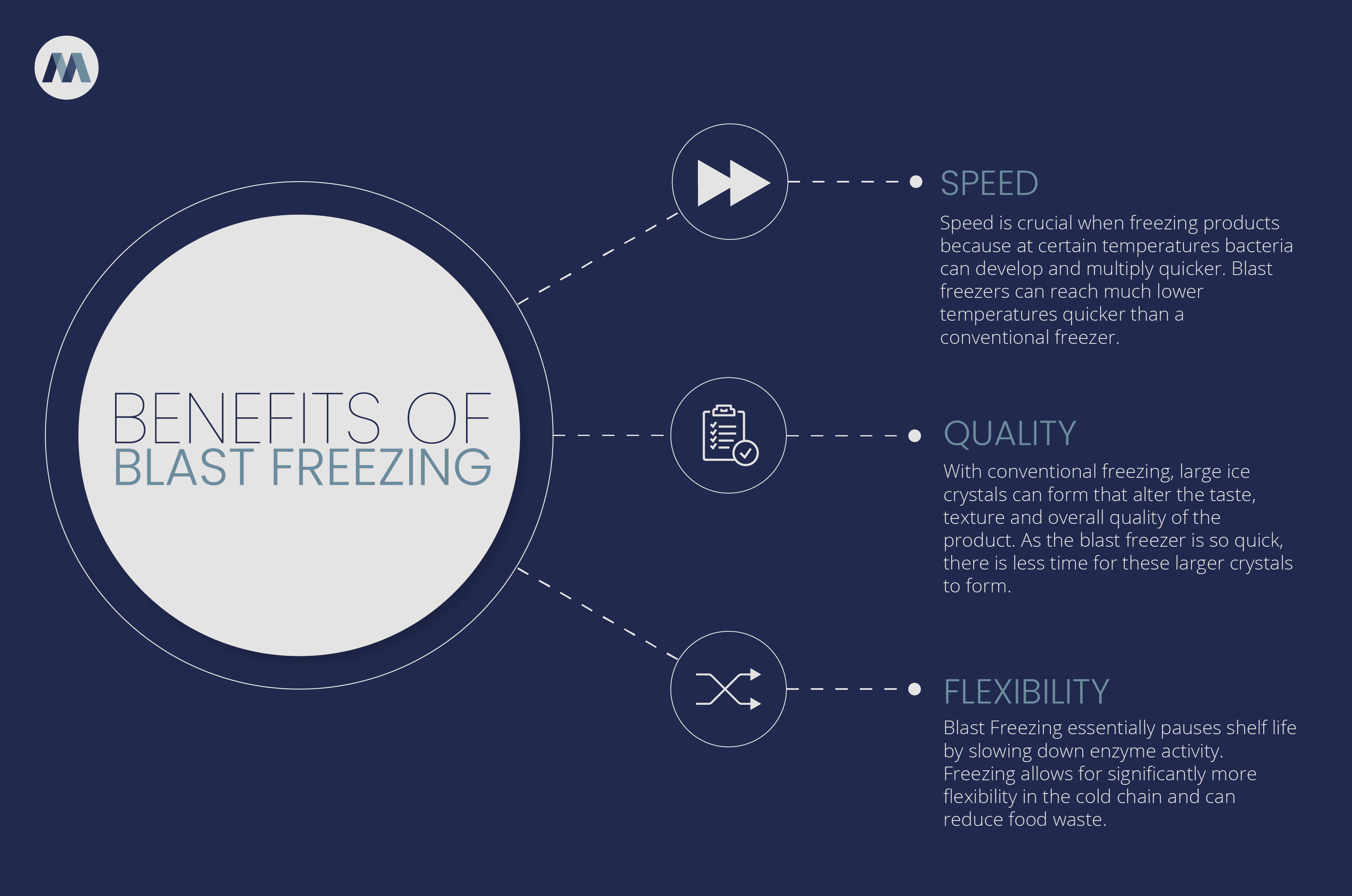

For bakery manufacturers looking to drive efficiency and reduce costs, blast freezing is an effective freezing method that can provide major benefits. Blast freezing is a rapid freezing method that uses extremely cold air circulated at high velocity to freeze products rapidly. This freezing method can help food manufacturers preserve product quality and freshness whilst creating cold chain flexibility.

Fast Blast Freezing Solutions

Unlike the traditional method of freezing, blast freezers can freeze bakery products such as dough, bread, cakes and pastries in a fraction of the time. Instead of days, the blast freezer can rapidly freeze bakery items in hours. The speed at which these products freeze is integral to the quality of the final product. The swift freezing action creates smaller ice crystals that cause less damage to cellular structures. This preserves texture and reduces moisture loss when thawing baked goods.

Enhancing your Supply Chain

Not only can blast freezing preserve the quality, taste and texture of your baked good, but the freezing process can significantly adapt your supply chain and production operations.

Creating Flexibility

Many bakeries blast freeze doughs which are utilised to produce many different types of products such as baguettes, rolls and loaves. Freezing dough can allow manufacturers to respond to demand.

Preserving Freshness

Freezing bakery products such as pastries and doughs before transportation is one of the best and most efficient ways to ensure freshness. By freezing, you can generate a lot more flexibility during distribution, which often leads to a lot less waste.

Choosing a Provider of Blast Freezing Services

Rather than invest in expensive in-house blast freezing systems, working with an experienced provider like Magnavale offers bakeries key advantages.

Lower Operating Costs

From energy usage to maintenance and repairs, owning blast freezers accumulates ongoing costs and liabilities. By outsourcing blast freezing, these costs and operational risks are handled by the provider.

Experience

We have provided blast freezing services for a range of customers for decades and have therefore developed expertise in blast freezing operations and best practices, making our operations highly efficient.

Flexibility

Production and demand fluctuations require freezing capacity adjustments. With outsourcing, utilised capacity can scale up or down as needed, rather than relying on fixed owned equipment.

Space Savings

In-house blast freezers take up precious factory floor space. Outsourcing keeps the equipment offsite and leaves more space for production.

If you are interested in blast freezing, please enquire below.

More on Blast Freezing Solutions

The Advantages of Blast Freezing

Magnavale has extensive experience providing blast freezing services for food manufacturers and distributors, as well as offering...

What is a Blast Freezer?

A blast freezer is a large, sealed unit that uses super-cooled forced air to rapidly freeze pallets of perishable food products. Unlike a...

Benefits of a Frozen Supply Chain

At Magnavale, we are huge advocates of freezing solutions and frozen warehousing. While not all chilled supply chains can be frozen, we...

Contact Us

Head Office:

Magnavale Ltd, Park Road,

Holmewood Industrial Park,

Chesterfield, S42 5UY