The Benefits of Blast Freezing

As well as offering BRC-certified temperature-controlled storage for primarily frozen & chilled food, Magnavale has extensive experience providing blast freezing services for food manufacturers and distributors. Many food producers seek blast freezing services to freeze their food product rapidly & consistently in bulk.

The blast freezing process can be carried out on a range of products such as:

- fruits & vegetables,

- proteins, like beef, chicken and turkey,

- fats, such as butter and cheese

- bakery items

Preserves Food Efficiently & Effectively in Bulk

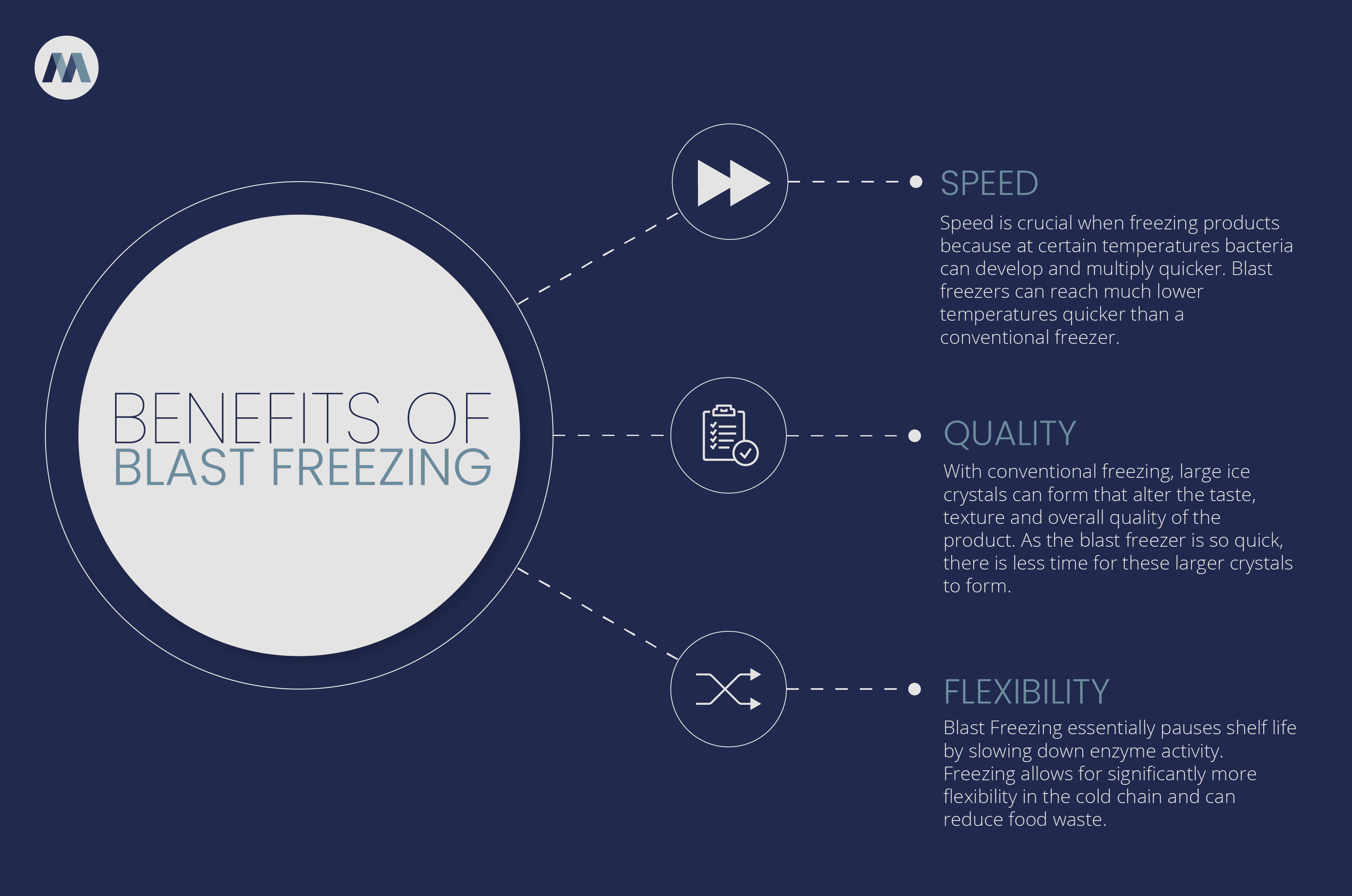

Blast freezing (flash freezing) is one of the most efficient ways to freeze food products in bulk. Our blast freezers reach temperatures of around -30°C, compared to household freezers which usually operate at around -18°C. The blast freezer, designed to hold palletised stock, can freeze product in bulk and do so much quicker than a typical freezer. Overall, the speed of the method can drastically reduce lost shelf life by reaching 0°C much faster.

Limit Ice Formation & Cell Deterioration

Conventional freezers, compared to blast freezers freeze food products much slower and this leads to the formation of larger ice crystals within plant and animal cells. The larger the ice crystallisation, the more likely it is that the cell wall is broken which can alter the taste, texture, quality and appearance of food products. As the blast freezer freezes so rapidly, the ice crystals are much smaller and denser, meaning less cellular damage which means using Blast freezers can maintain product quality, taste and texture.

Chilled on Receipt

Many of our customers that utilise our blast freezing services also utilise our frozen warehouse storage. This allows food manufacturers to deliver product to our cold stores chilled and have the product blast frozen as it enters our frozen storage facility. This service is often used for products that are despatched to supermarkets frozen, exported, or seasonal products that require long-term storage.

Freezing Through to the Core

Unlike conventional freezing, the blast freezing process involves separating layered palletised stock with a material known in the industry as eggshell. Eggshelling is a process that generates space between layers of palletised stock. The space between layers allows the forced air, generated by the blast freezer, to freeze down to the core of the product. Conventional freezing often freezes the outside of the product, leaving the centre of the product to freeze much slower, and as a result, stock can deteriorate due to the length of time taken.

Blast Freezing with Magnavale

At Magnavale, our team carry out bespoke individual validations to ascertain optimum freeze down times by product category allowing for an efficient supply chain process meaning stock can be available for supply significantly sooner. Overall, blast freezing is an essential step in the cold chain for many food manufacturers and distributors as it is currently one of the best ways to freeze palletised stock rapidly and consistently in bulk without altering the quality of the product.

For more information on blast freezing or frozen storage call 01246 858915 or make an enquiry below.

More News & Articles

What is Blast Freezing?

Blast Freezing: What it is and how it works. Using Blast freezing to preserve food quality and nutritional content. Intro Blast freezing...

Storage Solutions for Frozen Goods

Storage Solutions for Frozen Goods Our temperature-controlled storage solutions consist of ambient, frozen, and chilled warehousing, along...

Food Warehousing Services: Creating Efficiencies in your Cold Chain

As well as providing warehousing for the food sector, at Magnavale we provide a vast portfolio of value-added services which can be...

Contact Us

Head Office:

Magnavale Ltd, Park Road,

Holmewood Industrial Park,

Chesterfield, S42 5UY