Tray Washing Services

Automated tray & crate washing for food manufacturers. Our Chesterfield facilities utilise advanced equipment to deliver high-volume & retailer-compliant tray cleaning solutions.

Food-Safe Chemicals

We utilise only approved food-grade chemicals for washing trays and crates, ensuring rigorous sterilisation and hygiene standards are met.

24/7 Operation

With round-the-clock availability, our facilities align with your production schedules for tray washing anytime you require it.

Fully Automated

Our automated tray washers deliver high-volume, consistent cleaning tailored to your specifications with minimal labour.

Retailer-Compliant Tray Washing

At Magnavale, we understand the critical importance of proper tray hygiene for food manufacturers.

Our state-of-the-art automated tray washing facilities provide a thorough cleaning process to meet the highest standards.

With round-the-clock operations, we offer the flexibility businesses need to keep trays clean and ready for use.

Our Tray

Washing Procedure

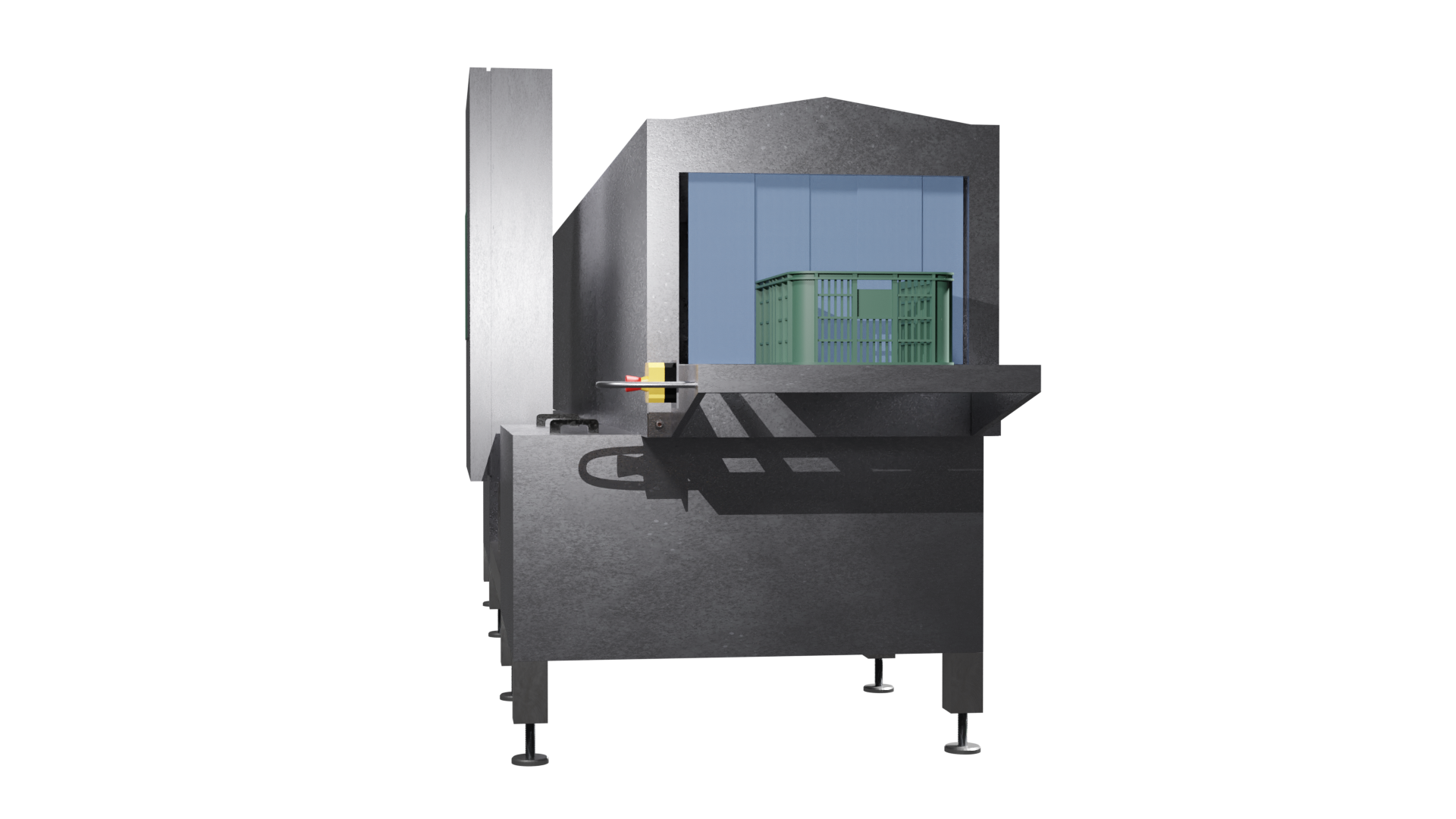

Once trays/crates arrive at our cold storage facility, they are sorted and loaded into industrial-grade tray washing tunnels.

The trays undergo a thorough cleaning process including an initial rinse to remove debris, washing with food-safe chemicals at high pressure and temperature, and a final rinse to eliminate any chemical residue.

Trays are restacked and a visual inspection ensures trays are sanitised to the highest standard.

Benefits of Outsourcing Tray Washing

Improve Efficiency

Our automated equipment and processes wash trays rapidly and consistently, providing greater throughput and turnaround times compared to in-house washing. This boosts efficiency and ensures a steady supply of clean trays.

Aligned Operations

With our facilities running 24/7, we can clean trays aligned to your production schedules, during times when in-house washing may be unavailable.

Reduce Costs

We invest in advanced automated tray washers designed specifically for high-volume food industry cleaning. This specialised equipment would involve major capital outlays for in-house purchasing.

Learn more about our cold chain services

Rapid Air Up-Tempering

In the food industry, maintaining product quality while efficiently managing temperature transitions is crucial. Rapid Air Up-Tempering is a highly effective method for bringing frozen food products to chilled temperatures in a controlled manner, ensuring a consistent...

Contract Packing & Repacking

Contract Packing At Magnavale we offer a variety of contract packing and repacking solutions from our UK facilities. Contract packing is the practice of outsourcing product packaging to a specialised company. This approach can be highly beneficial as it allows...

Date & Batch Code Printing

Date Coding & Batch Coding Date coding is one of many critical processes within food production. Best before and use-by dates are an integral piece of information for consumers so they must be legible. At Magnavale we offer date coding and many other...