How Microwave Tempering Works

How Microwave Tempering Works for Food Products

Intro;

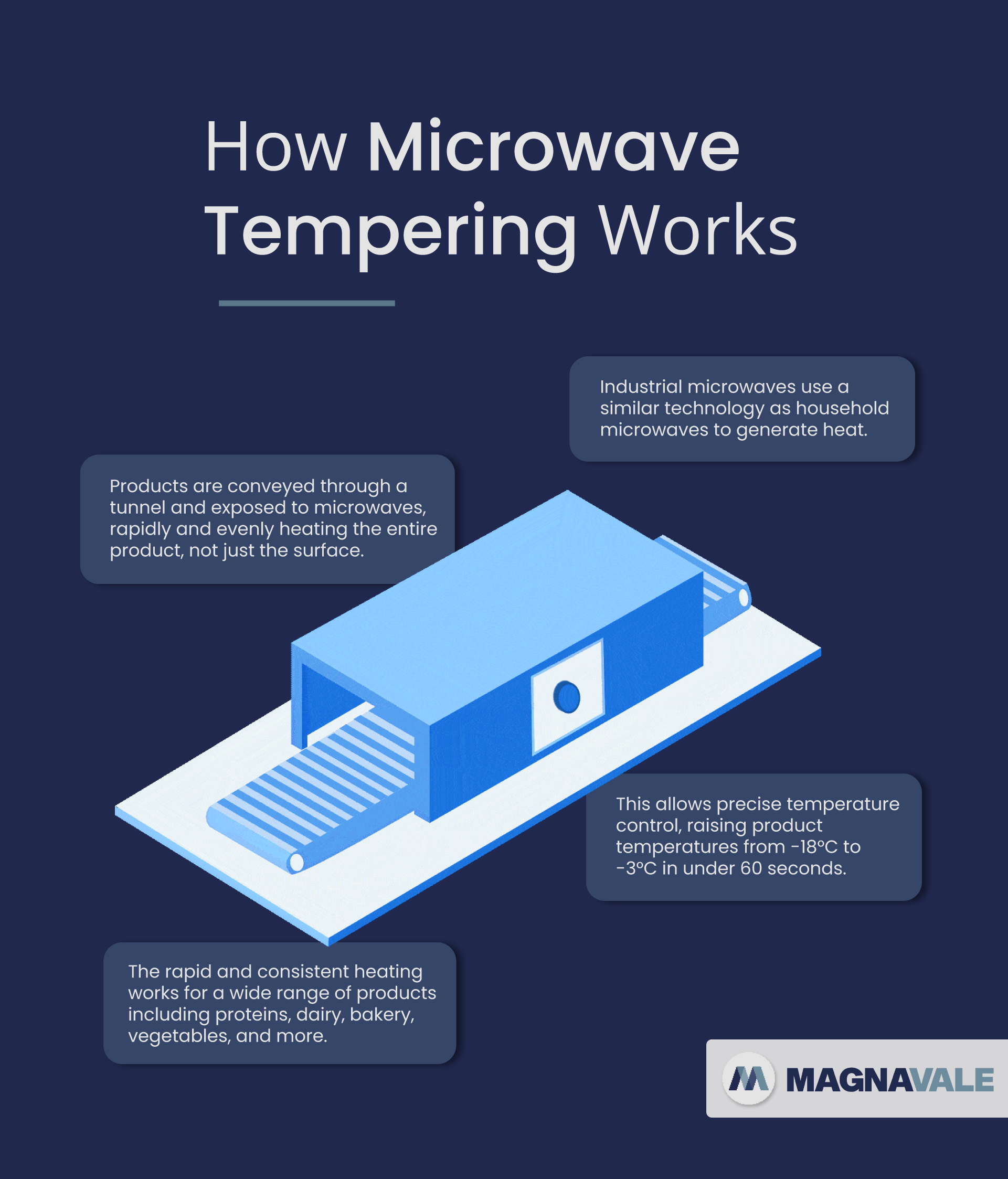

Microwave tempering, or defrosting is an advanced industrial technique that allows food manufacturers to raise the temperature of frozen products rapidly and consistently to chilled temperature levels, enabling efficient processing without compromising quality. Used across a wide range of food types—including meats, dairy, bakery goods, and vegetables—this method leverages industrial microwave tunnels to generate heat through intermolecular friction. This ensures deep, uniform tempering in under 60 seconds, far beyond surface-level thawing achieved by conventional methods.

Magnavale’s microwave tempering service offers exceptional precision, allowing products to be tempered from -18°C to -3°C with tight temperature control for specific manufacturing requirements. This process reduces handling, mitigates bacterial growth, improves consistency, and supports operational flexibility by allowing chilled dispatch straight from frozen storage. Combined with expert oversight and optional integration with rapid air tempering, microwave tempering delivers a fast, hygienic, and scalable solution for modern food supply chains.

Microwave Tempering (Defrosting) Processes for Food Products

Besides blast freezing, Magnavale also offers other food tempering services including microwave tempering.

Tempering technologies allow food manufacturers and retailers to raise the temperature of food products rapidly and consistently from frozen to chilled temperatures. Meaning food manufacturers can store food products frozen and dispatch those products chilled.

Industrial microwaves use the same technology you can find in your kitchen; the industrial microwave tunnel generates heat by producing intermolecular friction between the molecules of the product within the confines of the tunnel.

The product is loaded onto a conveyer belt and travels through the tunnel during which it is exposed to micro-waves which raises the internal temperature of the product. The product then exits the tunnel, is unloaded from the conveyer belt, has its temperature recorded and then any additional labelling or date coding conducted before being built back onto a pallet or into trays.

Our microwave defrost service ensures a highly consistent temper throughout the entire product, not just at surface level. Although small variances may occur for example between bone and fat in protein products, these can be managed efficiently by our expert technical team.

This process can be effectively used for various operations including meat tempering, dairy tempering, bakery thawing, defrosting, or softening of vegetables, and other industrial food defrost applications. With microwave tempering the core temperature can be raised from minus 18°C to minus 3°C in under 60 seconds.

Achieving Specific and Consistent Output Temperatures for Food

Crucially, for customers seeking an exact temperature output for manufacturing purposes, this can be easily achieved which is often required for production equipment that requires specific ingredient densities.

Many of our customers prefer this method of tempering due to the many benefits it yields for both the consumer and manufacturer. Microwaving offers consistent results which are critical to our customers and their consumers. This tempering method can reduce the time it takes to up-temper products, reduce handling of the product, reduce bacterial growth, and provide a consistent output temperature.

If you’re interested in our tempering services or any of our other frozen warehouse services call 01246 854999 or visit www.magnavale.co.uk/contact/

More on Microwave Tempering of Food Products

Rapid Air Up-Tempering

In the food industry, maintaining product quality while efficiently managing temperature...

Food Warehousing Services: Creating Efficiencies in your Cold Chain

As well as providing warehousing for the food sector, at Magnavale we provide a vast portfolio of...

A Guide to Batch Thawing: Microwave Up-Tempering

As a food processor, ensuring your frozen ingredients are properly thawed and ready for further...

The Difference Between Thawing and Up-Tempering

As well as providing temperature-controlled storage, we provide up-tempering solutions alongside...