Blast Freezing: What it is and how it works.

Using Blast freezing to preserve food quality and nutritional content.

Intro

Blast freezing is a rapid cooling technique that has revolutionised the way food is preserved across the cold chain. By freezing products to below -18°C in just hours using ultra-cold, forced air, this method ensures maximum retention of texture, flavour, and nutritional value, outperforming traditional freezing on every front. In this guide, we will explore what blast freezing is, how it benefits food manufacturers, and why industry leaders like Magnavale integrate it into end-to-end cold storage and food contract packing solutions across the UK. Whether you are seeking to cut costs, reduce spoilage, or optimise your supply chain, understanding blast freezing is essential for any food business striving for quality, compliance, and efficiency.

Blast Freezing in the Supply Chain

In today’s fast-moving food manufacturing and distribution landscape, speed, safety, and quality are paramount. One technology that plays a critical role in meeting these demands is blast freezing—also referred to as shock freezing, deep freezing, or flash freezing.

At Magnavale, we offer market-leading blast freezing services as part of our fully integrated cold chain solutions. Our facilities are strategically located across the UK, combining cold storage, food tempering, and food contract packing services under one roof. This makes us the ideal partner for manufacturers looking to cut cost, risk, and complexity from their cold storage UK operations.

What is Blast Freezing?

Blast freezing is a rapid cooling method used to reduce the temperature of food products to below -18°C in a matter of hours, using forced air at temperatures as low as -40°C. This method is vastly superior to traditional freezing techniques, which are slower and more likely to damage the product’s internal structures.

By freezing food quickly, smaller ice crystals are formed within the cells of the product. This preserves the cell structure, preventing the damage that leads to poor texture, taste, and nutritional degradation through drip loss. The result is a product that retains its freshness, flavour, and integrity even after extended storage.

Why Choose Magnavale for Blast Freezing?

- Capacity & Flexibility: each of our blast freezing units can accommodate thirty-three pallets at once and are suitable for a wide range of food categories—from meat and seafood to plant-based and dairy.

- Speed to Market: Our rapid cooling process means your product can be stabilised quickly and safely, ready for transport, storage, or packaging.

- End-to-End Service: With in-house cold storage, food contract packing, and tempering services, we support your entire supply chain from production to distribution.

How to Integrate Blast Freezing into Your Food Supply Chain

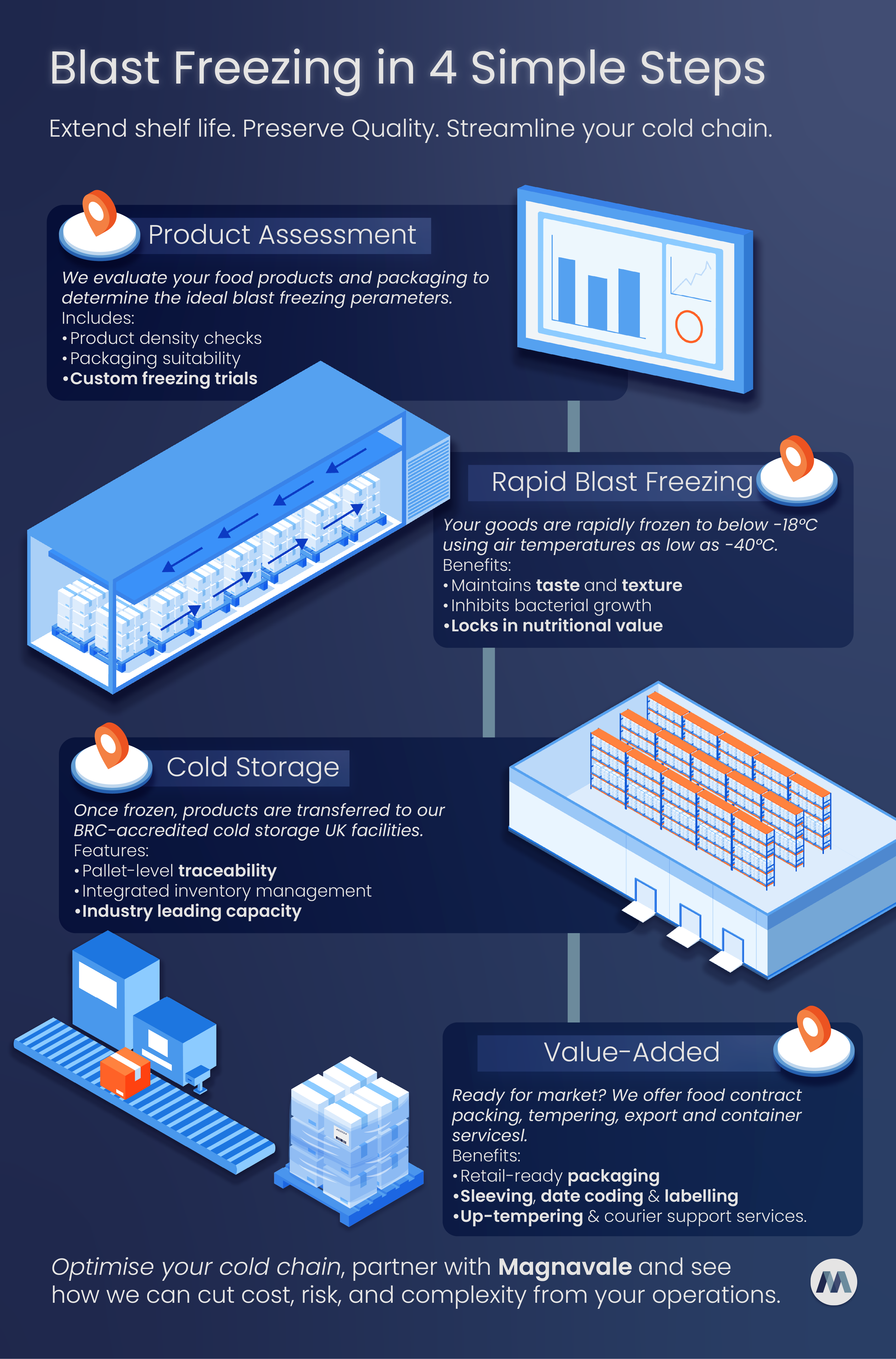

Implementing blast freezing into your process is simpler than you might think. Here is a step-by-step guide:

Initial Consultation

Begin by reaching out to the Magnavale team. We assess your product type, packaging, and throughput requirements to determine the most effective blast freezing solution for your business.

Product Testing

We conduct controlled validation trials to assess freeze times based on product density and packaging. This step ensures optimal performance without compromising product quality.

O All movements are managed under strict cold chain protocols and our advanced Warehouse Management Systems (WMS) ensures you can track and monitor your products from intake to despatch down to the individual box to enable full traceability

Blast Freezing

Your products are rapidly frozen in our state-of-the-art blast freezing chambers. With real-time monitoring, we ensure all items reach the correct core temperature quickly and safely.

Cold Storage

Once frozen, your goods can be transferred directly into our cold storage UK facilities. Our warehouses are BRC-accredited and fully temperature-controlled to maintain your product’s integrity.

Value-Added Services

Need more than just storage? With on-site food contract packing and tempering, we can repack, label, sleeve, or even up-temper your product when required—ready for final distribution or retail.

Blast Freezing – Summary

Blast freezing is not just about freezing food—it is about preserving quality, extending shelf life, and safeguarding your brand reputation. For manufacturers and food businesses that value efficiency and excellence, Magnavale’s blast freezing services provide a powerful way to futureproof supply chains.

To find out how we can support your operation with blast freezing, cold storage UK, and food contract packing, contact us today or visit our website for more information. Let Magnavale be your partner in frozen food excellence.

More on Frozen Warehousing & Blast Freezing

Chilled Pallet Storage UK Food Retailers & Manufacturers.

Chilled Pallet Storage for Food Retailers and Manufacturers across the UK. Magnavale operates...

Magnavale Opens New Cat 3 Storage Facility in Lincolnshire

Magnavale Opens New Cat 3 Storage Facility in Lincolnshire We are very pleased to announce...

Direct – To – Consumer. Pick & Pack.

Magnavale: Your Trusted Partner for D2C Cold Chain Fulfilment. Here at Magnavale, we offer a...

Magnavale Easton: Complete.

We are very proud to announce the official opening of Magnavale Easton. The facility has capacity...