How De-Topping Can Cut Unnecessary Transport Costs

In today’s landscape of rising fuel prices, food manufacturers and distributors constantly seek innovative solutions to reduce transport costs and enhance efficiencies within the cold chain. As fuel prices and environmental concerns continue to rise, one cold chain solution that has been extremely beneficial to our partners is de-topping.

What is De-Topping?

To de-top a pallet means reducing its overall height to align with warehouse racking or other supply chain infrastructure. This process complements the over-stacking process, forming a strategic approach to maximise space utilisation during transportation.

This process involves stacking pallets above the industry-standard height of 1.68 meters, allowing businesses to transport more stock in a single trip. By using this method, businesses can significantly reduce the number of required journeys, leading to substantial cost savings and environmental benefits.

How a De-Topping Service Works

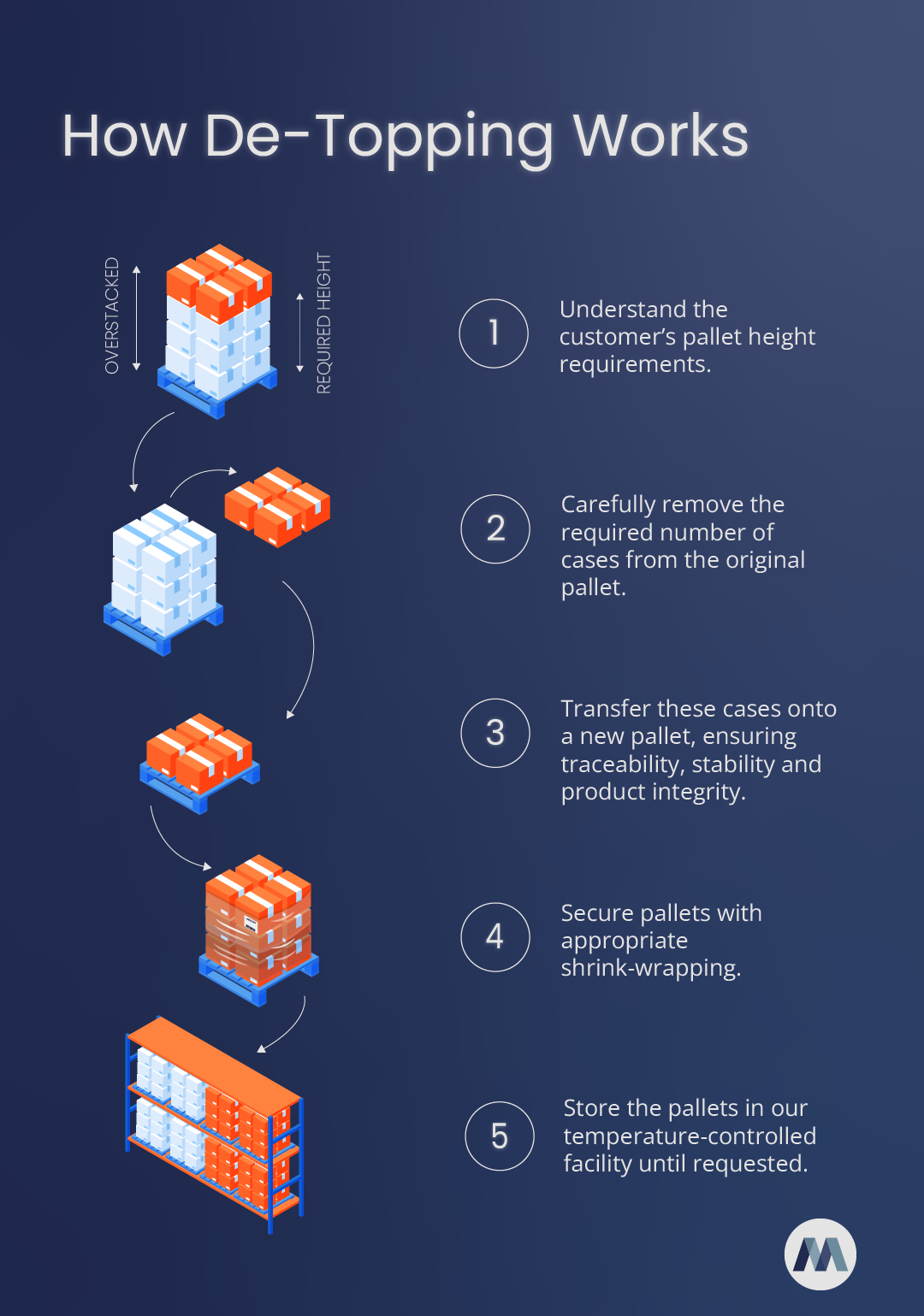

At Magnavale, we conduct our de-topping services with care and precision. Upon arrival at one of our temperature-controlled facilities, our expert team carefully assesses each pallet. From here, our team:

- Understand the customer’s pallet height requirements.

- Carefully remove the required number of cases from the original pallet.

- Transfer these cases onto a new pallet, ensuring traceability, stability and product integrity.

- Secure pallets with appropriate shrink-wrapping.

- Store the pallets in our temperature-controlled facility until requested.

Benefits of De-Topping

Using our de-topping service offers numerous advantages for businesses:

Cost Savings

The cost saved in the long run can be significant for businesses. By reducing the number of required journeys, businesses can reduce transport and the associated resources with transport.

Sustainability

Environmental benefits are significant. Fewer journeys result in reduced carbon emissions, and lower fuel consumption contributes to resource conservation. More efficient use of storage space reduces overall energy requirements for temperature control.

Flexibility

Our de-topping service offers adaptability to various racking systems and storage configurations.

Where are we based

If you are interested in our de-topping and temperature-controlled storage solutions we have storage facilities situated across the UK in Chesterfield, Easton, Warrington and Scunthorpe, all with pallet de-topping capabilities.

For any enquiries or questions, please fill out a contact form and we will be in touch shortly.

More News & Articles

Magnavale Proud to Support Bolsover Town FC U10

We are pleased to announce the sponsorship of the talented Bolsover Town FC U10 team. With our sponsorship, the team have purchased away...

Combating UK Food Insecurity Crisis with Fareshare & 2 Sister’s Food Group

We are incredibly proud to collaborate with our strategic valued partners 2 Sister’s Food Group and Fareshare, to help combat the...

New Shoes for Grantham Kids

The Magnavale Easton team was extremely pleased in the last few weeks to have supported a Rotary Club scheme in Grantham providing new...

Contact Us

Head Office:

Magnavale Ltd, Park Road,

Holmewood Industrial Park,

Chesterfield, S42 5UY