Guidance on Storing Food Produce at Magnavale

Whether you are a growing business outsourcing for the first time or a large established brand considering moving your account, there are a number of factors to evaluate when choosing a temperature-controlled storage provider.

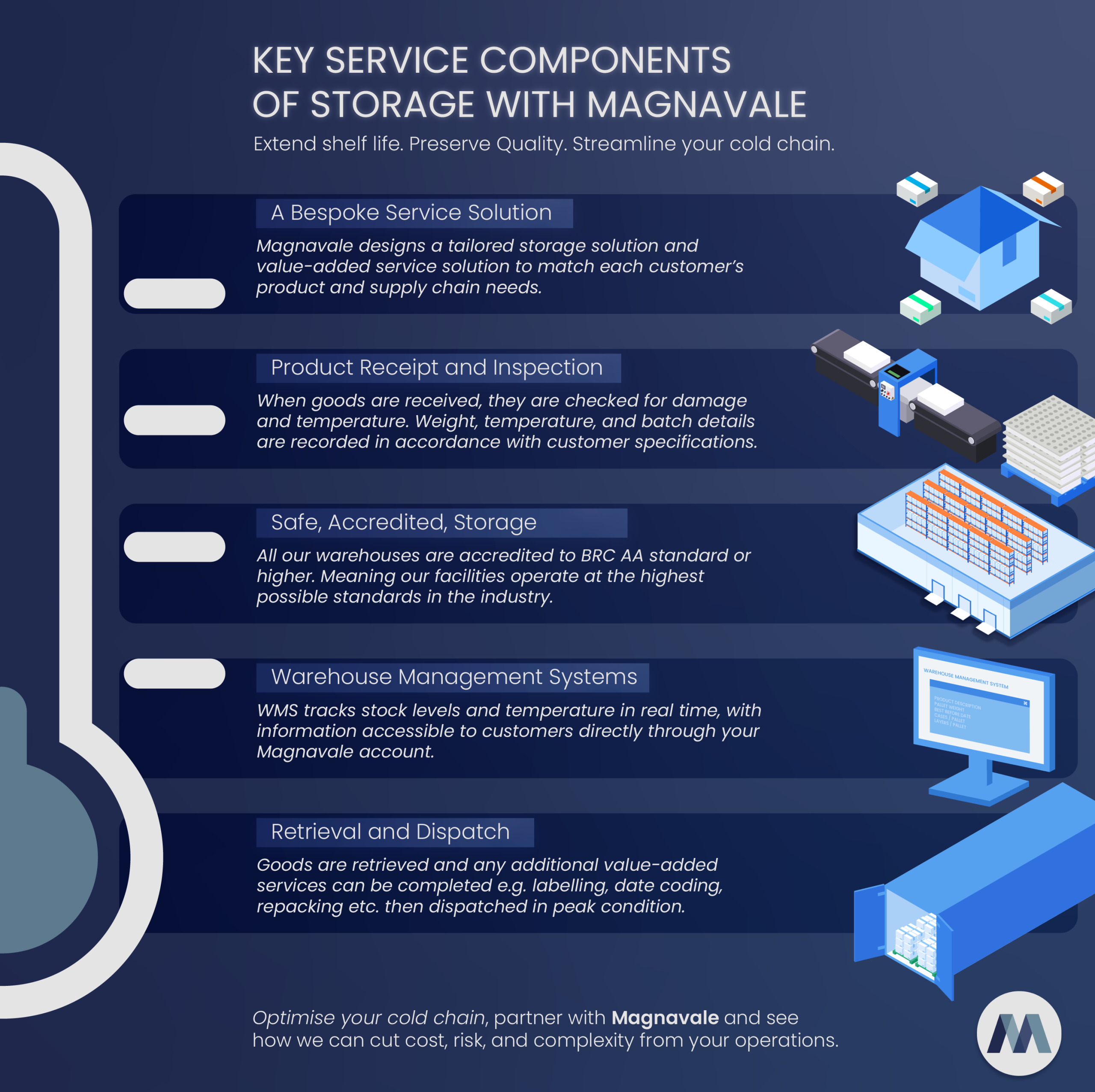

Magnavale is one of the UK’s largest providers of temperature-controlled storage for food. With over 30 years of experience supporting food manufacturers, producers, importers, and retailers, our national network of facilities offers ambient, chilled, and frozen food warehousing solutions designed to meet the demands of food industry supply chains.

Pallet Formats – UK, Euro, Over-height, or Oversize

We provide temperature-controlled storage from our sites at Easton, Chesterfield, Scunthorpe, and Warrington, providing our customers with facilities that are strategically located for efficient onward national distribution.

Not all storage providers have racking that is capable of managing the full range of pallet formats, however, our network is equipped to intake any pallet format required, including over-height and non-standard formats.

Where stock arrives in non-UK-standard or mixed pallet presentations, we can offer handling services such as pallet inversion and handballing of cases, baskets, or trays. These services allow our customers to reconfigure their goods into formats suitable for retailers, bulk storage, or export.

Temperature-Controlled Storage

It is important to remember that your products may require differing temperatures between skus, or at different stages of your supply chain. It is important to choose a provider that is equipped to store all your products. We offer flexible temperature-controlled storage solutions tailored to individual customer requirements:

- Ambient storage

- Chilled storage

- Frozen storage

All Magnavale facilities operate with automated temperature monitoring and recording systems, enabling continuous oversight and compliance with customer specifications and food safety standards. This ensures product integrity is maintained throughout the storage period.

Value Added Services

Do your products require additional services to prepare them for the next steps in the supply chain? Labelling, date-coding, packing, or blast freezing? Choosing to have these services conducted by your storage provider can reduce cost, risk and complexity compared to shipping them to an additional handling location.

Our decades of experience and close consultation and collaboration with our customers and partners has helped Magnavale develop a portfolio of value-added services in addition to food warehousing.

Two of our most popular services for frozen storage customers are blast freezing and up-tempering.

- Blast freezing rapidly reduces product temperature to frozen levels immediately after arrival, effectively pausing shelf life and preserving product quality compared to traditional freezing methods.

- Up-tempering, typically conducted shortly before despatch, carefully raises the temperature of frozen products back to chilled conditions, allowing controlled re-entry into the chilled supply chain.

These services are often used together at different stages of the supply chain to maximise flexibility and reduce waste.

The process to open an account

- Make an enquiry via our enquiries inbox (enquiries@magnavale.co.uk), or directly through our enquiries form on our website

- One of our team will contact you directly to discuss your requirements.

- After we have a firm understanding of your requirements, we will issue you with a new customer form that confirms the details of your solution and the pricing associated with each service.

- Once returned we will set up your account, and you will be free to schedule your first intake of stock.

If you would like to discuss ambient, chilled, or frozen storage, or explore how our value-added services could support your food supply chain, please visit www.magnavale.co.uk/contact

Q&A

What is temperature-controlled food storage?

Temperature-controlled food storage refers to warehousing environments that maintain specific ambient, chilled, or frozen temperature ranges to protect food safety, quality, and shelf life. These environments are essential for food manufacturers, importers, and retailers managing perishable or frozen products.

What types of temperature-controlled storage does Magnavale offer?

Magnavale provides ambient, chilled, and frozen food storage, allowing customers to store multiple SKUs at different temperatures or move products between temperature zones as supply chain requirements change.

Can Magnavale store non-standard or over-height pallets?

Yes. Magnavale’s facilities are equipped to manage UK, Euro, over-height, oversize, and non-standard pallet formats. Where required, additional handling services such as pallet inversion or handballing can be provided to reconfigure goods for storage or onward distribution.

How do I open a food storage account with Magnavale?

Customers can make an enquiry via Magnavale’s website or enquiries inbox. After discussing requirements, a new customer form is issued outlining services and pricing. Once completed, the account is set up, and stock intake can be scheduled.

Who is temperature-controlled food storage suitable for?

Temperature-controlled storage is suitable for food manufacturers, producers, importers, and retailers at all stages of growth, from businesses outsourcing storage for the first time to large established brands reviewing their supply chain strategy.

More on Frozen Warehousing & Blast Freezing

Chilled Pallet Storage UK Food Retailers & Manufacturers.

Chilled Pallet Storage for Food Retailers and Manufacturers across the UK. Magnavale operates...

Rapid Air Up-Tempering

In the food industry, maintaining product quality while efficiently managing temperature...

Magnavale Opens New Cat 3 Storage Facility in Lincolnshire

Magnavale Opens New Cat 3 Storage Facility in Lincolnshire We are very pleased to announce...

What is Blast Freezing?

Blast Freezing: What it is and how it works. Using Blast freezing to preserve food quality and...